Quality Control

XYZ Aerospace takes quality control to its highest standards. We are continually improving upon our quality control practices throughout our facility and our daily operations. Starting off by utilizing some of the best CNC equipment in the industry, we have the ability to consistently produce components with ultra-tight tolerances. Our CNC machining centers maintain a positional accuracy and repeatability of +/- .00005.

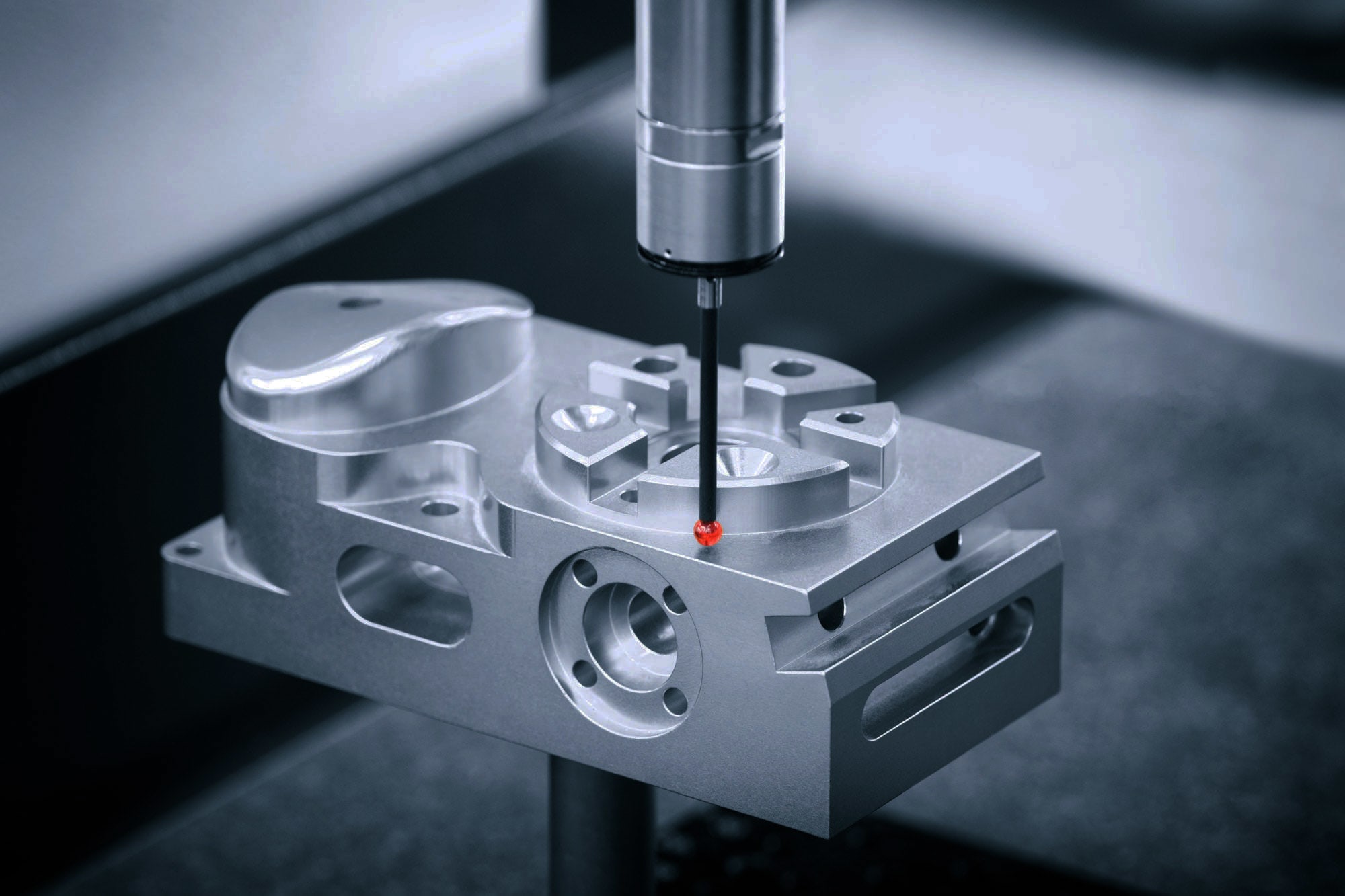

Not only does XYZ Aerospace use top of the line CNC machining centers, but we also incorporate the reliability and accuracy of using Renishaw probing cycles. Renishaw is the leader in the industry when it comes to dependability, accuracy, and repeatability. The use of a Renishaw probe allows us to be able to measure critical dimensions directly in the machine during the machining process.

Using a Renishaw probe this way allows us to guarantee quality throughout our machining processes. Not only can we precisely measure the most critical of dimensions but use of a Renishaw helps us to reduce cost as well. From faster set up times, along with less part-to-part variation scrap, rework and concessions are all reduced. There is also considerably less down time having to remove a part from the machine again and again to check critical dimensions. XYZ Aerospace maintains quality control by investing in some of the most advanced and reliable equipment within our industry. We strive to deliver 100% quality parts produced in accordance with the drawing specifications every time.